Batavia Container Office Buildout and Design Lab Electrical Work

ELECTRICAL INSTALLATION | EXTENDING EXISTING CIRCUITS | DRYWALL RESTORATION

IOC Construction is proud to have partnered with Batavia Container Inc. to enhance their office space and design lab in Batavia, IL. The project encompasses two key areas: the conference room and the design lab/cutting area. The work includes electrical installations, drywall modifications, and finishing touches to ensure a high-quality outcome.

Problem Identified

During the planning phase, it was discovered that the existing electrical infrastructure in both the conference room and design lab was not positioned to support the necessary power and data needs.

The conference room lacked dedicated receptacles for an integrated power solution at the table, while the design lab required additional electrical and data connections to optimize workflow and equipment use. This presented a challenge in ensuring a functional and efficient setup without causing major disruptions to daily operations.

Solution Implemented

To address these challenges, IOC Construction devised a plan that minimized disruption while effectively integrating the required electrical modifications. In the conference room, we installed under-carpet tile power tape to discreetly run power to the table, avoiding intrusive conduit work.

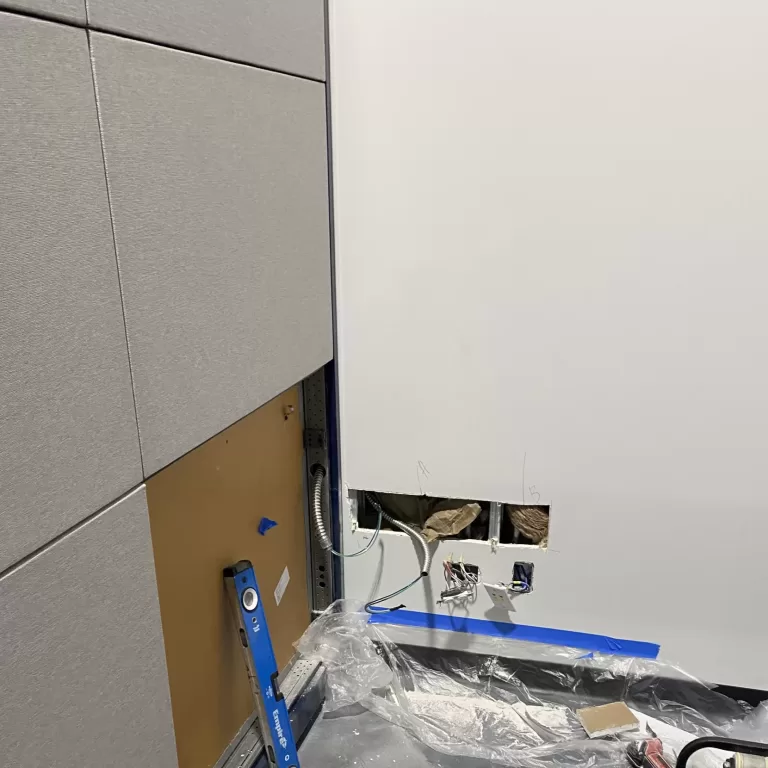

In the design lab, we extended existing circuits and installed additional junction boxes, carefully opening and restoring drywall to maintain a seamless finish. Our team coordinated with Batavia Container’s management to schedule work strategically, ensuring minimal impact on daily operations.

Conference Room Electrical Enhancements

- Removal of drywall and carpet tiles as needed for electrical installation.

- Installation of two new electrical receptacles using under-carpet tile power tape.

- Restoration of affected drywall, including taping, sanding, priming, and spot painting.

Design Lab and Cutting Area Upgrades

- Installation of four additional junction boxes by opening drywall and extending existing circuits.

- Addition of two electrical receptacles in the cubicle area.

- Installation of two data drops for improved connectivity.

- Drywall restoration, including taping, sanding, priming, and spot painting.

Project Execution and Standards

- The job site was kept clean, with daily debris removal and secure work areas.

- All materials and installations followed manufacturer specifications and industry best practices.

- A detailed work schedule ensured clear communication and coordination with the client.

Commitment to Quality

IOC Construction prioritizes precision, efficiency, and minimal disruption to operations. By integrating modern electrical solutions into Batavia Container’s workspace, this project enhances productivity, supports operational needs, and provides a well-structured office and design lab environment.