The 12 Questions Most GCs Avoid —And How We Handle Them

If you’ve worked with enough general contractors, you know the difference between those who deflect and those who take responsibility. At IOC Construction, we believe complex projects deserve direct answers. We’ve built our systems and our reputation around being ready to answer tough questions honestly and effectively.

These are 12 questions architects and engineers often ask when they’re evaluating a general contractor and the kinds of responses that signal experience, preparation, and accountability. If you get vague, defensive, or overly polished answers, that’s a red flag.

1. Can you walk me through your coordination process?

Our coordination starts with a detailed preconstruction review and continues with structured check-ins and a shared platform for field notes and conflicts. Our team uses consistent check-ins with design consultants and flags issues before they land in the field.

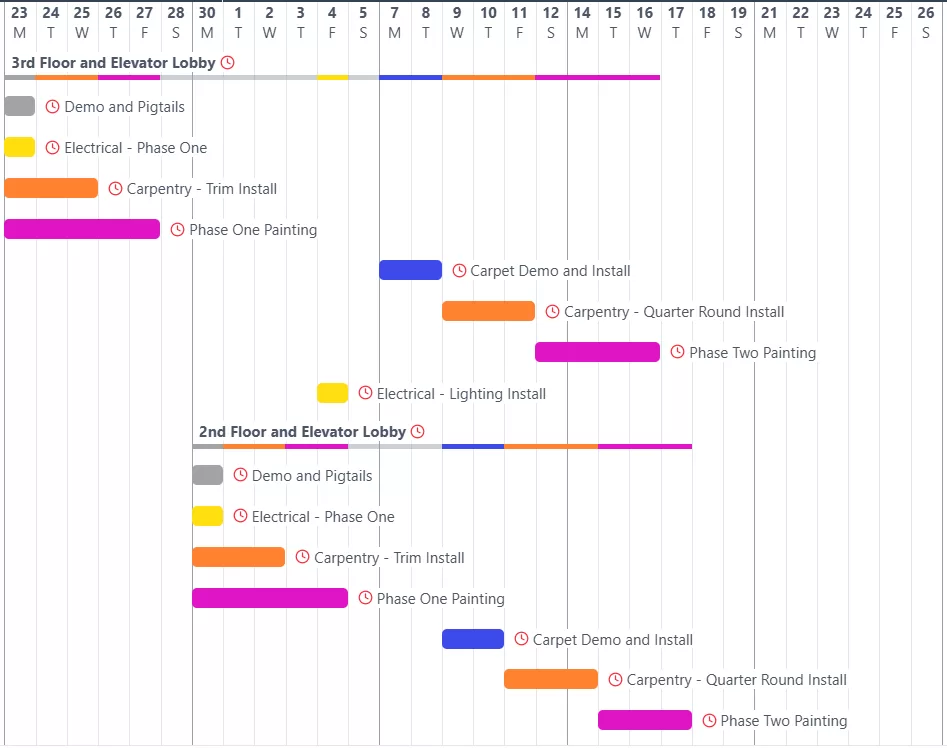

To further streamline communication, we use JobTread as a centralized, client-facing tool where documentation is organized and accessible in real time. It serves as a hub for everything from project details to daily updates, ensuring that schedules, milestones, and decisions are always visible and up to date for our team and our clients alike. Here’s one example of the scheduling information we make available for our clients:

2. Who’s tracking submittals and RFIs?

Every project has a dedicated project manager who oversees the entire process, including managing RFI and submittal logs. Our preconstruction process identifies potential challenges early to minimize RFIs.

Regularly scheduled project update meetings with all stakeholders ensure that any pending submittals are addressed promptly. Our project management team oversees this process to ensure all stakeholders have the information they need to make timely, informed decisions.

3. How do you handle mistakes in the field?

Unfortunately we’ve made them, like every GC. What makes us different is how we respond. If we stumble you can expect quick and concise information, constant updates on corrective measures, clean documentation, and a rapid response to mitigate the issue and make appropriate repairs if necessary.

As part of our commitment to continuous improvement, IOC Construction conducts an internal After Action Review for every field-related issue. This interdepartmental meeting allows our teams to:

Analyze what happened and why

Identify actionable steps to prevent similar issues in the future

Document lessons learned and update internal processes accordingly

This structured approach ensures that we learn from every challenge and deliver an even stronger performance on the next project.

4. What does IOC’s safety program look like?

At IOC Construction, safety is a company-wide priority woven into every part of our operations. Our safety program is built on proactive training, cross-departmental collaboration, and continuous improvement.

All staff—whether in the field or the office—are OSHA 10 or OSHA 30 certified. From project managers and estimators to marketing associates and executives, everyone completes safety training. This unified approach ensures that safety is part of our company culture.

IOC also has a dedicated Safety Committee with representatives from every department—including Sales, Estimating, Finance, Compliance, and Production. This diverse group meets regularly to review protocols, analyze incidents, and suggest updates to keep our teams safe and informed.

Lastly, we update our company’s safety policies on a regular basis. Our safety manual is revised annually and continuously refined to reflect evolving industry trends, best practices, and insights gained from our own field experience.

5. What happens if permitting or inspections cause delays?

Permitting and inspection delays can derail even the best-planned projects. We take a proactive approach to navigating these potential roadblocks with a dedicated Permitting and Compliance Team focused solely on managing approvals and municipal coordination.

Our team has established strong working relationships with municipalities throughout the Chicagoland area, allowing us to anticipate requirements, avoid unnecessary delays, and streamline the permitting process.

As soon as a contract is signed, our permitting specialists begin coordinating with local agencies and guide you through every step.

To stay ahead of changing regulations, our project leads receive ongoing code updates through industry training and local association briefings. This ensures every project stays compliant and on track from day one.

6. How do you handle budget overrun?

We address budget concerns from day one. Our Sales and Estimating teams work closely with clients to define scope, understand financial limits, and explore options like phased construction to ease constraints.

We proactively flag potential unforeseen costs during the bidding process and include contingency strategies to reduce surprises later on. With thoughtful planning and clear communication, we aim to keep your project on budget and avoid unexpected cost increases.

7. What’s your actual change order process?

Clear documentation, zero drama. You’ll see the reason, cost, and time impact. As soon as a question or concern arises, we bring it to the table. Our priority is to be open, transparent, and quick to communicate. We want owners to feel fully informed and involved in the decision-making process.

IOC is committed to a true partnership approach. We present all available information so you can make the choice that’s best for your project. Our job is to help you find the best solution for your goals.

8. How do you maintain quality without slowing down the schedule?

It comes down to smart preplanning and strong supervision. We hold detailed preconstruction and coordination meetings to map out critical scopes before work begins. This allows us to sequence the project efficiently and anticipate potential issues.

We document progress as we go and aren’t afraid to pause if something seems off. Cutting corners only leads to rework, delays, and added costs—everything we aim to avoid. By planning ahead and staying hands-on, we protect both the schedule and the quality of the final product.

9. Can I talk to another architect or engineer you’ve worked with?

Absolutely. We’re proud of our long-term relationships and they’ll give you the full story. Our partners will tell you we’re engaged, listen and react, and if things don’t go as planned we’re quick to pivot and find a solution.

10. What’s your approach if the schedule slips?

We run short-interval schedules and make trade-level adjustments when needed. If the critical path shifts, we bring solutions.

During regularly scheduled project meetings, the schedule is always reviewed in detail, including any positive or negative variations. You’ll never hear “we’ll figure it out later.” Instead, we communicate early, offer clear options, and work collaboratively to stay on track.

11. What do you do when specs are vague or conflicting?

We raise the flag early, and suggest clarifications or alternates. We’d rather ask a tough question than build something wrong.

From the start, we collaborate with all stakeholders to understand the ownership’s goals for the project. That insight guides our recommendations, so when we suggest clarifications or alternatives, they’re aligned with the bigger picture and what matters most to you.

12. How do you handle closeout?

We assign closeout to someone early on in the process so that punchlist tracking, document control, and warranty info isn’t an afterthought.